1.Cables classified by material

Polyvinyl chloride (PVC) cables:

Widely used in industrial automation. Suitable for environments with moderate mechanical stress and good tolerance to different chemicals. Most suitable for low and medium voltage application scenarios. one

Polyurethane (PUR) cables:

Suitable for withstanding high mechanical stress, it can easily handle high wear situations in many industrial applications. It has high flame retardancy, can resist welding sparks, and can prevent the growth of microorganisms inside the sheath, thereby avoiding bacterial transmission. For example, the DRAG800X highly flexible PUR data signal drag chain cable is suitable for mobile applications under high mechanical stress, such as frequent continuous bending in drag chain systems; Polyurethane control drag chain cables are also suitable for high flexibility PUR material control drag chains, etc. twelve

POC cable:

It has very high mechanical strength and a heat resistance of 150, capable of withstanding extremely hot environments and suitable for high-temperature applications such as welding activities or sparks. However, all 8 wires are wrapped with insulated cables, and there is no shielded wire protection between the wires and cables, so it is mainly used for local Ethernet with less noise interference.

2.Network related cables

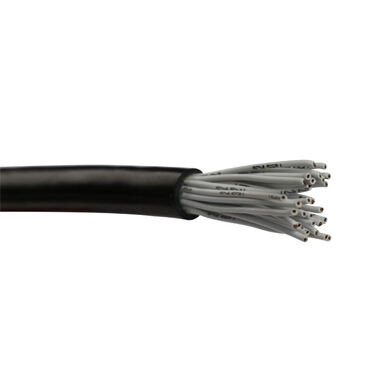

Shielded twisted pair (STP) cable:

This is a twisted pair cable with 8 wires, each consisting of 4 pairs, protected by shielded wires between the wires and cables. It is the most widely used network cable in industrial automation applications, but it is more expensive than UTP cable. one

Coaxial cable:

A medium for transmitting data in the form of low voltage electricity, consisting of five layers. The first layer is a plastic cover that serves as a shielding layer for the entire cable; The second layer is an insulator wrapped in metal, which serves to prevent noise; The third layer is a conductor made of metal woven fabric, foil, or a combination of both; The fourth layer is the insulation shielding layer, and the last layer is the copper conductor. This cable has strong resistance to signal interference from fluorescent lamps, motors, or other types.

3.Other cables

Fiber optic:

Composed of a cladding (low-density glass or plastic), a core, and an outer layer of fibers, light passes through the optical fiber according to the principle of internal reflection. Although the specific application advantages in industrial automation are not explicitly mentioned, they belong to the cable types that may be used in industrial automation.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

GA

GA

BE

BE

LA

LA

MN

MN

SU

SU

UZ

UZ

XH

XH