What is the performance of drag chain cables in industrial applications?

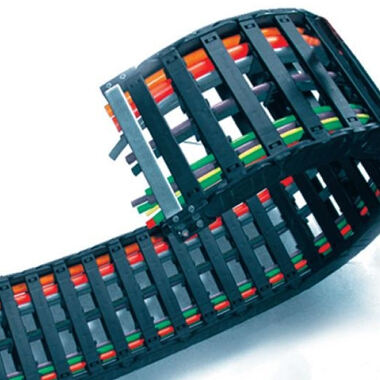

Drag chain cables, as an important component of industrial automation, are widely used in various complex industrial environments. Its unique structure and material selection enable drag chain cables to exhibit excellent performance under harsh working conditions, providing reliable guarantees for the stable operation of industrial equipment. Let's take a look at the performance of drag chain cables in industry .

1. Bending resistance and mobility

The design of the drag chain cable fully considers its dynamic working environment in the drag chain system. Due to the frequent bending and movement of drag chains during equipment operation, drag chain cables must have excellent resistance to bending and movement. Drag chain cables usually use multi strand precision twisted anti bending oxygen free fine copper wire as the conductor, combined with high mechanical performance insulation materials, to ensure that the cable can maintain stable electrical performance under high-frequency bending and stretching. The bending radius of the drag chain cable is small, which can flexibly adapt to various narrow spatial structures, making equipment installation more convenient.

2. Wear resistance and high flexibility

Friction and collision between equipment are inevitable in industrial environments. The surface of the drag chain cable has been specially treated to have excellent wear resistance, which can effectively resist the wear caused by chain friction and extend the service life of the cable. The high flexibility of drag chain cables makes them less prone to breakage during bending and movement, maintaining a stable electrical connection. The combination of high flexibility and wear resistance enables drag chain cables to perform well in various complex industrial situations.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

GA

GA

BE

BE

LA

LA

MN

MN

SU

SU

UZ

UZ

XH

XH